Welcome To Metson Machines

Mineral Water Plant Manufacturer Providing 10+ Years of Reliable Solutions

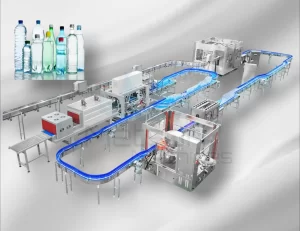

Metson Machines is one of the reputable mineral water plant manufacturers in Ahmedabad, Gujarat, India, offering a wide selection of high-quality mineral water plants that are easy to install, operate, and maintain. We manufacture fully-automatic and semi-automatic water purification systems ranging from 250 LPH to 60,000 LPH capacity, suitable for a wide range of industries. Our plants are customized as per clients’ requirements with complete solutions for RO systems, filtration units, UV treatment, ozone dosing, bottling, capping, labeling, and packaging. We only use the highest grade stainless steel and food-grade components to ensure hygienic, efficient, and long-lasting performance of every plant.

We are experts in the field of mineral water plant manufacturing and regularly cater to the demands of the beverage, healthcare, hospitality, education, FMCG, and industrial sectors. Our plants are highly preferred by clients in these industries for their quality, reliability, and compliance with BIS, WHO, and international water purification standards.

Over the years, we’ve built a strong reputation as one of the most trusted designers and producers of top-grade mineral water plants known for durability, efficiency, and minimal maintenance. With a deep understanding of industry requirements and government norms, we design systems that deliver safe, pure, and great-tasting drinking water in every drop. You may select from a wide range of capacities and configurations – and we can even customize your plant layout and automation level based on your specific operational needs.

Mineral Water Plant Manufacturer in Ahmedabad, India

Since our establishment, we have been producing high-performance, cost-effective mineral water plants using advanced technologies and top-quality materials. Our systems ensure smooth operations and consistent water purity throughout the process. If required, we can supply turnkey projects including machinery, piping, electrical, and installation support.

Mineral Water Plant Exporter

We supply our high-quality mineral water plants across India and export to countries including Nepal, Bangladesh, Tanzania, Saudi Arabia, United Arab Emirates, Kenya, Sri Lanka, UAE, Oman, Nigeria, Indonesia, Bhutan, and many more. Once you decide to set up a mineral water plant, just let us know your capacity and layout needs – and we’ll guide you to the best available solution. Our team is experienced in delivering customized and turnkey mineral water solutions.

Specifications of Mineral Water Plant

- Capacity Range: 250 LPH to 60,000 LPH (Custom Capacity Available)

- Material Used: Stainless Steel 304/316 (Food Grade)

- Automation: Semi-automatic / Fully-automatic

- Water Source: Borewell / River / Municipal Supply

- Application: Bottled Water, Jar Filling, Industrial Use

- Plant Type: RO Plant, UV, UF, Ozonation, Filtration

- Power Source: Electric

- Packaging Options: Bottles, Pouches, Cans, Jars

Features of Mineral Water Plant:

- Robust Construction

- Corrosion Resistant

- Long Operational Life

- Low Maintenance

- Fully Customizable

- Energy Efficient

- BIS/ISI/WHO Standard Compliance

#1 Filling Machines

#2 Labelling Machines

#3 Jar Washing & Filling Machine

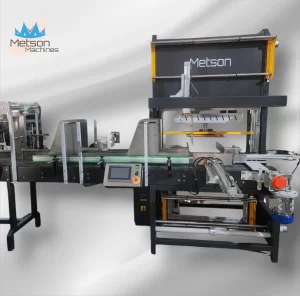

#4 Shrink Wrapping Machine

#5 Blow Moulding Machine

MISSION

To manufacture reliable, efficient, and affordable machinery for the mineral water and beverage industry. We aim to empower clients with turnkey solutions that drive growth and operational excellence.

VISION

To become a globally recognized leader in water plant and packaging machinery manufacturing. We strive to innovate, scale, and set benchmarks in quality, service, and technology.

QUALITY

Our machines are built with precision, durability, and compliance with industry standards like BIS and FSSAI. Each unit undergoes strict quality checks to ensure consistent performance and minimal maintenance.

Looking to set up a mineral water plant?

Click Here

Request A Quote

Frequently Asked Questions:

Get every single answers from here.

To engineer reliable, high-performance mineral water plant solutions that deliver purity, efficiency, and long-term value backed by precision, integrity, and customer-centric innovation.

We follow rigorous quality protocols to meet BIS and global standards in every mineral water plant we manufacture. Our in-house QA process guarantees high-performance, leak-proof, and contamination-free mineral water plants.

We are an authorized and certified manufacturer of mineral water plants, meeting all relevant compliance and industry requirements.

BIS Certification (IS 14543/13428), FSSAI License, ISO 9001, Material Test Certificates, Water Test Reports (NABL), Pollution Control NOC, Factory License, and Packer Registration are essential for setting up and operating a compliant mineral water plant.

Domestic Clients (India)

MOQ for standard mineral water plants: 1 complete unit (e.g., 1000–5000 LPH)

MOQ for customized plants: 1 unit, based on specifications

MOQ for spares/components: 10 units (varies by item)

Export Clients

MOQ for export orders: 1 complete plant (subject to documentation and logistics)

Bulk export MOQ: 3 units per shipment (for dealers or OEMs)

MOQ may vary by plant capacity and country-specific compliance

Yes, we are a fully registered vendor, compliant with all statutory and industrial requirements.

Registered under MSME (Udyam Registration) as a recognized manufacturing unit.

ISO 9001:2015 certified for maintaining quality management systems in production.

Listed on the GeM (Government e-Marketplace) portal for public procurement eligibility.

NSIC (National Small Industries Corporation) registered for participation in government tenders.

Hold valid Pollution Control Board NOC, Factory License, and all local industrial approvals.

Equipped with Material Test Certificates (MTC) and other QA documentation for raw materials.

Provide BIS-compliant system designs as per IS 14543 / IS 13428 standards for packaged drinking water.

Certified for vendor partnerships with various EPC contractors and institutional buyers.

All vendor registration documents and compliance certificates are readily available upon request.

Yes, we offer complete shipping and transportation support for all mineral water plant orders.

Domestic delivery available across India via trusted logistics partners.

Export logistics handled with proper documentation, packaging, and coordination with freight forwarders.

All systems are securely packed and crated to prevent damage during transit.

Transportation charges and delivery timelines are shared clearly at the time of quotation.

Support for doorstep delivery, FOB, CIF, or custom shipping terms as per client requirement.

We coordinate with clients for smooth unloading and installation readiness at the site.

We follow a well-defined production schedule and maintain buffer stock of critical components.

All projects are tracked through internal project management systems for on-time execution.

Pre-dispatch inspections and quality checks are done before shipment to avoid delays.

We partner with reliable transport and logistics providers for prompt and safe delivery.

Delivery timelines are committed clearly in advance and strictly adhered to.

We offer complete installation and commissioning support for all mineral water plants.

Dedicated technical support team available for troubleshooting via call, video, or on-site visits.

Warranty coverage for key components as per contract terms.

Spare parts supply and AMC (Annual Maintenance Contract) options available.

Operator training, maintenance manuals, and performance monitoring guidance are provided post-installation.